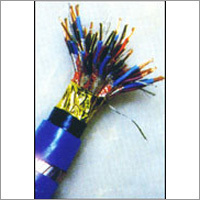

Foundation Fieldbus Cables

200 INR/Meter

Product Details:

- Number of Conductor 2 (twisted pair)

- Diameter Approx. 7.5 mm

- Core Number 2

- Usage & Applications Fieldbus networks, automation, hazardous environments, process industries

- Dielectiric Strength 2000V AC/1 min

- Cable Type Twisted pair, shielded

- Tensile Strength > 1500 N (depends on construction)

- Click to View more

X

Foundation Fieldbus Cables Price And Quantity

- 200 INR/Meter

- 50 Meter

Foundation Fieldbus Cables Product Specifications

- 2000V AC/1 min

- 100 m, 200 m, 500 m, Custom lengths available

- Foamed PE (Polyethylene)

- PVC (Polyvinyl Chloride)

- Aluminum/polyester tape with tinned copper drain wire

- Green jacket; cores: black & blue

- 2 (twisted pair)

- 300V

- Fieldbus networks, automation, hazardous environments, process industries

- Depends on packaging; typically supplied on reels

- Tinned copper

- 2

- Approx. 7.5 mm

- Circular

- 100 15% (at 31.25 kHz)

- Silver/Gold (dependent on connector type, not on standard cable)

- Solid or stranded

- Tinned copper, Foamed PE, PVC, aluminum/polyester tape

- Approx. 12 kg/km

- Foamed PE

- > 1500 N (depends on construction)

- Tinned copper

- Process automation, Field instrumentation, Industrial control systems, Distributed control systems (DCS), Foundation Fieldbus communications

- Twisted pair, shielded

- Green

- Indoor/Outdoor, Tray, Direct burial (armored)

- Foundation Fieldbus Cable

Foundation Fieldbus Cables Trade Information

- 1000 Meter Per Day

- 1-7 Days

- All India

Product Description

Foundation Field Bus Cables

We provide efficient Compensating Cables for meeting various industrial requirements of our clients. These cables are also known as a perfect alternative to Thermocouple Extension Cables because they are available at competitive prices. Thermocouple cables being offered by us are manufactured using different alloys of superior quality. These cables are widely brought into application by steel, cement and glass industries.

Designed for Demanding Industrial Applications

Foundation Fieldbus Cables are developed to meet the critical needs of process automation, field instrumentation, and distributed control systems (DCS). With rugged construction, these cables excel in challenging environments, offering both high performance and long-lasting reliability. Their robust, moisture-resistant structure ensures uninterrupted communication in harsh and potentially hazardous areas, supporting the stringent requirements of the modern process industry.

Superior Electrical and Fire Safety Performance

Engineered for safety, these cables feature low smoke emission and are available in halogen-free formats upon request. They demonstrate a dielectric strength of 2000V AC for one minute and maintain a maximum conductor resistance of 24 /km at 20C. With a foamed PE insulation and PVC outer jacket, these cables guard against signal loss and offer comprehensive protection in sensitive installations.

Flexible Installation and Configurations

Supplied in various lengthsincluding 100 m, 200 m, 500 m, and custom sizesFoundation Fieldbus Cables adapt seamlessly to diverse site layouts. Their typical diameter of 7.5 mm, minimum bend radius of 10x diameter, and typical outer sheath thickness of 1.5 mm enable easy handling and neat installation in trays, conduits, or for direct burial. Whether for indoor or outdoor use, these cables are crafted for versatile deployment.

FAQs of Foundation Fieldbus Cables:

Q: How should Foundation Fieldbus Cables be installed to ensure maximum performance and longevity?

A: To optimize signal integrity and durability, install Foundation Fieldbus Cables with a minimum bend radius of 10 times the overall diameter. They support indoor, outdoor, tray, and armored direct burial installations. Proper routing and protection from mechanical stress or extreme moisture will maximize cable lifespan and performance.Q: What makes these cables suitable for process automation and hazardous environments?

A: These cables deliver 100% shield coverage to minimize electromagnetic interference, feature robust moisture resistance, and offer a low smoke, halogen-free construction option. This ensures reliable communication and enhanced safety in process automation, hazardous environments, and safety-conscious industrial settings.Q: When is it necessary to use the halogen-free version of this cable?

A: The halogen-free version is recommended for sites with strict fire safety requirements or where minimizing toxic gas emission during fire is critical. This variant reduces health risks and potential equipment damage, making it ideal for enclosed, populated, or mission-critical environments.Q: Where can Foundation Fieldbus Cables be utilized within industrial sites?

A: These cables are designed for use throughout industrial plantsin control rooms, field instrumentation areas, and hazardous process zones. Their resilience and shielding make them suitable for distributed control systems, fieldbus networks, and both indoor and outdoor runs, including direct burial with optional armored construction.Q: What are the benefits of the cables foamed polyethylene insulation and tinned copper conductors?

A: Foamed PE insulation significantly reduces capacitance and attenuates electrical noise, ensuring superior signal clarity over long runs. Tinned copper conductors offer enhanced conductivity and corrosion resistance, boosting both transmission reliability and cable longevity.Q: How can I order Foundation Fieldbus Cables in custom lengths or configurations?

A: You may request custom lengths and specific configurations directly from the manufacturer or supplier in India. The cables can be supplied on reels according to your project specifications, facilitating tailored solutions for unique site or system requirements.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Contact Us

Contact Us Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free