Water Cooled Power Cables

200 INR/Meter

Product Details:

- Dielectiric Strength > 15 kV/mm

- Core Material Copper

- Number of Conductor Single Core or custom multiple cores

- Tensile Strength >= 250 N/mm

- Locking Type Screw or Clamp fitting (as per design)

- Conductor Shape Stranded/Rope lay

- Operating Temperature Continuous operation up to 110C

- Click to View more

X

Water Cooled Power Cables Price And Quantity

- 200 INR/Meter

- 50 , , Meter

Water Cooled Power Cables Product Specifications

- Depends on cable size & length Customized options

- Continuous operation up to 110C

- Stranded/Rope lay

- Screw or Clamp fitting (as per design)

- >= 250 N/mm

- Rubber/Silicone

- Single Core or custom multiple cores

- Copper

- > 15 kV/mm

- Available from 1 Meter up to 10 Meters or customized

- High conductivity, Robust water cooling, Flexible, Durable, Corrosion resistant joints

- Copper, Rubber, Contacts of Brass/Bronze

- Braided Copper or other conductive material

- Low impedance, typically < 0.01 Ohms/m

- Oil and heat resistant rubber/silicone

- Electrolytic Grade Copper

- Water Cooled Power Cable

- Red, Black, Customization possible

- Copper cross section 95 mm to 3000 mm

- 600V 1000V AC or customized as per requirement

- Up to 110C

- Red, Black, or customized

- High quality EPDM / Rubber / Silicone insulation

- Flexible, manually or mechanically assisted installation

- Flexible copper conductor

- 1 (Single core standard)

Water Cooled Power Cables Trade Information

- 1000 , , Meter Per Day

- 1-7 Days

Product Description

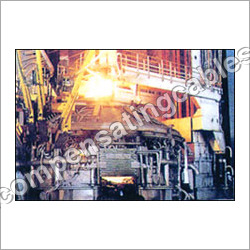

In tune with defined industry standards, we are engaged in manufacturing, exporting and supplying a high quality range of Water Cooled Power Cables. The offered cables are manufactured by making use of supreme grade raw materials and the latest technology under the supervision of our experienced professionals. These cables are used for induction melting or heating equipments. The offered Water Cooled Power Cables are available in various specifications to meet the precise needs of the clients at highly competitive prices.

Key Features:

- Rust proof

- Excellent performance

- Maintenance free

- Excellent durability

Enhanced Heat Dissipation

Our water cooled power cables utilize continuous water circulation to efficiently dissipate heat, supporting high-current applications while maintaining reliable electrical performance. This feature significantly extends cable lifespan, improving operational stability even under intensive use.

Superior Flexibility and Durability

Constructed with flexible stranded or rope-lay copper cores and high-quality EPDM, rubber, or silicone insulation, these cables are easy to install manually or with mechanical assistance. The robust materials provide excellent mechanical strength and chemical resistance, ideal for repeated bending and harsh industrial conditions.

Customizable Solutions for Every Need

Our cables can be tailored to your specific requirementsincluding dimensions, cable color, connector type, length, and number of conductors. Various jacket materials and shielding options are available, ensuring a precise match for your operating environment and electrical demands.

FAQs of Water Cooled Power Cables:

Q: How are water cooled power cables installed and connected?

A: Water cooled power cables can be installed either manually or with mechanical assistance, depending on size and application. Connections are made using threaded or flanged water inlet/outlet fittings as specified, with locking options including screw or clamp fittings for secure and leak-proof joints.Q: What industries typically use these water cooled power cables?

A: These cables are commonly used in steel plants, foundries, welding operations, and other heavy industrial environments where high electrical conductivity, efficient cooling, and resistance to heat, oil, and chemicals are critical for safe, continuous power delivery.Q: When should I consider customizing the cable design?

A: Customization is valuable when standard cables do not fit your operational needsfor example, if you require specific lengths, cross-sectional areas, special insulation materials, connector types, or color coding. Customizations can optimize performance and safety in your unique application.Q: What process ensures leak-proof performance in these cables?

A: Each cable undergoes 100% leak-proof testing under hydraulic pressure up to 30 bar. This rigorous testing guarantees that the cable will perform reliably without any leakage during operation in demanding industrial environments.Q: Where should these cables be used for optimal benefit?

A: These cables are best employed in settings with high ambient temperatures and intensive current loads, such as induction furnaces, welding equipment, and power transmission lines in harsh manufacturing conditions, where advanced heat management and durability are essential.Q: How does continuous water cooling enhance cable longevity?

A: Continuous water circulation through the cable removes excess heat generated during operation. This prevents overheating, minimizes thermal stress on insulation and conductors, and significantly extends the service life of the cable, reducing maintenance downtime and investment in replacements.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Contact Us

Contact Us Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free