Instrumentation Cables

200 INR/Meter

Product Details:

- Number of Conductor Up to 61 pairs or customized

- Core Material Tinned Copper

- Impedance 100 ohms (typical for paired cables)

- Tensile Strength High tensile strength (as per IS 1554)

- Usage & Applications Used in process plants, power plants, chemical plants, oil & gas industry, manufacturing units

- Conductor Shape Round

- Conductor Type Solid or Stranded

- Click to View more

X

Instrumentation Cables Price And Quantity

- 200 INR/Meter

- 50 Meter

Instrumentation Cables Product Specifications

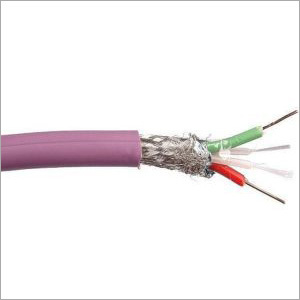

- Aluminium Mylar with tinned copper drain wire

- PVC or XLPE

- High tensile strength (as per IS 1554)

- Black

- Black, Grey, or as specified

- Tinned Copper

- 100 ohms (typical for paired cables)

- Up to 61 pairs or customized

- Instrumentation Cable

- Up to 1100V

- Indoor and Outdoor installation, Conduit, Trunking, or direct burial

- No locking mechanism

- Annealed Tinned Copper

- PVC

- Copper, PVC, XLPE, Aluminium Mylar, Steel

- 0.5 sqmm to 2.5 sqmm

- 2.5 kV for 1 minute

- Solid or Stranded

- 5 mm to 20 mm (depending on cable type and cores)

- Varies as per cable specification

- PVC or XLPE insulated

- 100 meters (standard), customizable lengths available

- Varies as per cable size and packing

- Used in process plants, power plants, chemical plants, oil & gas industry, manufacturing units

- Black or Grey

- Round

Instrumentation Cables Trade Information

- 1000 Meter Per Day

- 1-7 Days

- All India

Product Description

With several success records in our portfolio and dream to achieve more, we are engaged in offering an exclusive collection of Instrumentation Cables. Highly acclaimed in OGP industries, the provided cables are used in transferring data and voice transmission signals. Offered cables are manufactured with high precision using premium quality raw materials and the latest manufacturing procedures. Our clients can avail these Instrumentation Cables from us in different lengths, thicknesses and other specifications at reasonable rates.

Features:

- Durable finish standards

- Flexibility

- Excellent physical & electrical properties

- Corrosion resistance

Precision and Safety in Signal Transmission

Instrumentation cables ensure superior signal integrity and minimal interference with 100% aluminium mylar tape screening and conductors of annealed tinned copper. Rigorous testing (dielectric strength and insulation resistance) guarantees excellent performance even in harsh industrial conditions. Available in various sizes, insulation, and jacket materials, these cables provide secure transmission in demanding applications.

Compliance and Versatility

Adhering to IS 1554, BS 5308, and IEC 60228, our cables withstand flame, oil, and environmental hazards, making them suitable for conduit, trunking, or direct burial in diverse locations. RoHS and REACH compliance assure environmental safety, while customizable lengths and constructions address the specific needs of each project.

FAQs of Instrumentation Cables:

Q: What are instrumentation cables and where are they typically used?

A: Instrumentation cables are specially designed for transmitting low-level signals in precise control and measurement applications. They are widely used in process plants, chemical plants, oil & gas industries, power plants, and manufacturing units for reliable and accurate data transfer.Q: How do the specified standards (IS 1554, BS 5308, IEC 60228) benefit the user?

A: These standards ensure the cables meet stringent requirements for safety, electrical performance, and durability. Compliance guarantees reliability, uniformity, and suitability for demanding industrial environments, giving users confidence in cable quality and performance.Q: What flame and oil resistance properties do these cables offer?

A: The cables undergo flame retardant testing as per IEC 60332 and 60754, and oil resistance per IEC 60811. This assures the cables maintain integrity when exposed to fire or oils, crucial for hazardous industrial settings.Q: Can the cable length, conductor count, and packing be customized according to project needs?

A: Yes, instrumentation cables can be tailored with customizable lengths, conductor arrangements (up to 61 pairs or more), and various packing options including coils and wooden drums to suit different installation and project requirements.Q: What is the recommended minimum bending radius for installation?

A: A minimum bending radius of 12 times the cables overall diameter is advised. This helps prevent mechanical damage and ensures long-term reliability during and after installation.Q: How does the screening and insulation design protect signal integrity?

A: The cables feature 100% screening using aluminium mylar tape with a tinned copper drain wire. Combined with high insulation resistance (>500 M/km at 500 V DC) and robust dielectric strength (2.5 kV for 1 min), this design minimizes electromagnetic interference and signal loss.Q: What are the environmental and safety compliances for these cables?

A: Instrumentation cables comply with RoHS and REACH standards, ensuring they are environmentally safe and meet current health and safety regulations, making them suitable for global industrial applications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Contact Us

Contact Us Send Inquiry

Send Inquiry Send SMS

Send SMS