Device Net Cables

200 INR/Meter

Product Details:

- Conductor Shape Round

- Core Number 4 or 5

- Install Type Fixed or Flexible

- Rated Temperature -20C to +80C

- Insulation PVC

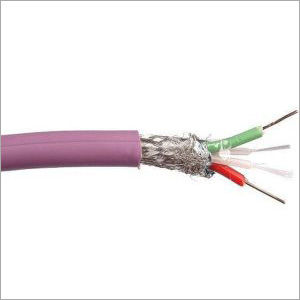

- Cable Type Twisted Pair Shielded Multi-Core

- Usage & Applications Network Protocol Communication in Industrial Automation

- Click to View more

X

Device Net Cables Price And Quantity

- 50 , , Meter

- 200 INR/Meter

Device Net Cables Product Specifications

- -40C to +85C

- 5.5 mm to 8.0 mm

- As per length and cable diameter

- 4 or 5 Core

- Standard Locking Connectors

- Polyvinyl Chloride (PVC), Polyethylene

- DeviceNet Cable

- 1 m to 100 m (Custom Lengths Available)

- Tinned Copper Braiding

- Depends on length

- PVC, Copper

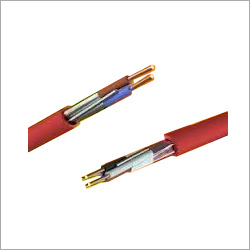

- Black or Yellow

- >1500V

- Copper

- High

- Flexible, Durable, Flame Retardant, Oil Resistant, Superior EMI/RFI Shielding

- Network Protocol Communication in Industrial Automation

- Industrial Automation, PLCs, Sensor Networks, Communication Systems

- Twisted Pair Shielded Multi-Core

- PVC

- PVC

- -20C to +80C

- Round

- 4 or 5

- Fixed or Flexible

- 22 AWG

- Bare Copper

- 120 Ohm (Nominal)

- Yellow / Black

- Yellow, Black

- 300V

- -20C to +80C

- Stranded

Device Net Cables Trade Information

- 1000 , , Meter Per Day

- 1-7 Days

Product Description

Mechanical Characteristics (Overall)- Operating Temperature Range: -20 degree C To +75 degree C

- UL Temperature Rating: 75 degree C

- Bulk Cable Weight: 108 lbs/1000 ft.

- Max. Recommended Pulling Tension: 190 lbs.

- Min. Bend Radius/Minor Axis: 4.800 in.

Robust Construction for Demanding Environments

These cables feature UV-resistant PVC outer jackets with a thickness of at least 1.5 mm, providing superior protection against harsh weather and industrial environments. With a flame test rating of UL VW-1 and a fire rating of IEC 60332-1, they ensure maximum safety and compliance wherever installed.

Versatile Applications in Industrial Automation

Device Net Cables are designed for reliable network protocol communication in PLCs, industrial automation setups, and sensor networks. They support both digital and analog signals and are available in custom lengths and configurations to suit fixed or flexible installations.

Exceptional Performance and Reliability

Engineered with stranded copper cores, these cables provide low capacitance (<60 pF/m), high impedance (120 Ohm nominal), and superior shielding effectiveness (>80 dB), minimizing voltage drops and electromagnetic interference for consistent communication.

FAQs of Device Net Cables:

Q: How do Device Net Cables maintain signal quality in industrial settings?

A: Device Net Cables utilize twisted pair shielded multi-core designs with tinned copper braiding, ensuring more than 80 dB screening effectiveness. This significantly reduces EMI/RFI interference, maintaining stable digital and analog signal transmission even in high-noise environments.Q: What installation options are available for these cables?

A: Device Net Cables can be installed in both fixed and flexible setups. Their minimum bend radius of five times the cable diameter allows for easy routing, while the robust construction and locking M8/M12 connectors ensure secure connections in industrial environments.Q: When should I consider using Device Net Cables for my automation system?

A: These cables are recommended when reliable, secure communication is necessary between PLCs and sensors, particularly in environments requiring fire retardancy, oil resistance, and superior EMI/RFI shielding. Custom lengths and core configurations offer adaptability for your automation needs.Q: Where are these cables typically used?

A: Device Net Cables are widely used in industrial automation, PLCs, sensor networks, and communication systems, particularly in settings where flame retardancy, UV resistance, and oil resistance are critical for safety and durability.Q: What benefits do the flame retardant and UV resistant properties offer?

A: Flame retardant ratings (UL VW-1 and IEC 60332-1) enhance fire safety, while UV resistance prevents cable degradation in outdoor or harsh lighting environments. Both features extend operational lifespan and reduce maintenance costs.Q: How is the correct cable length or configuration determined for a project?

A: Length and configuration depend on your installation layout and protocol requirements. The cables are available from 1 m to 100 m and can be customized in reel or coil formats, with options for 4 or 5 core setups to suit a variety of industrial applications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Contact Us

Contact Us Send Inquiry

Send Inquiry Send SMS

Send SMS